| Load rating and life |

|

The dynamic load rating of the bearings given in this catalogue and the relationship between dynamic load and bearing fatigue life are determined based on ISO 281.Improvements in materials and manufacture enable TCB bearings to claim higher dynamic load rating.

|

.jpg) Dynamic load rating Dynamic load rating |

|

The dynamic load rating is defined as the load that can be applied to the bearing which offers a basic L10 rating life of one million revolutions. This is the life associated with 90% reliability which has been found by experience to be accepted for normal engineering bearing applications.

|

.jpg) Relationship between load and life Relationship between load and life |

|

Due to the discreteness of the material fatigue, bearings of the same design operating at the identical conditions will take on different lifes. The rating life is expressed by the total number of revolutions or the number of hours at constant speed reached or exceeded by 90% of this bearing group before the first signs of material fatigue appear.

The standardized calculation method for dynamically stressed rolling bearings is based on the theory of material fatigue. The following equation defines the relationships among basic rating life, basic dynamic load rating and equivalent dynamic load.

|

|

Ball bearings

|

.jpg) |

| Roller bearings |

.jpg) |

|

Life shall be represented by hours when rotating speed keeps constant.

|

| |

.jpg) |

|

where

|

| L10 ú║basic rating life (90% reliabilityúČ revolutions) |

| L10h ú║basic rating life (90% reliabilityúČoperating hours) |

|

C ú║basic dynamic load rating (KN)

|

| (radial bearing CrúČthrust bearing Ca ) |

|

P ú║equivalent dynamic load (KN)

|

| (radial bearing PrúČthrust bearing Pa ) |

|

n ú║rotating speed ( r / min )

|

For more sophisticated life reliability, the equation

can be modified by |

.jpg) |

|

.jpg) |

|

where

|

: adjustment rating life[(100-n)% reliabilityúČ revolutions] : adjustment rating life[(100-n)% reliabilityúČ revolutions] |

: adjustment rating life[(100-n)% reliabilityúČoperating hours]

|

| ai : life adjustment factor for reliability ( see table of ai ) |

Equivalent dynamic load |

|

Radial bearings are often subjected to radial and axial load simultaneously. If the resultant load is constant in magnitude and direction, then equivalent dynamic load Pr can be calculated by

|

| Pr=XFr+YFa |

| where |

| Fr : actual radial load (KN) |

| Fa : actual axial load (KN) |

| X : radial dynamic load factor |

|

(see table of XúČY) |

| Y : axial dynamic load factor |

| Values for factors X and Y |

.jpg) |

Static load rating Static load rating |

|

The value of static load rating Cor in this catalogue is calculated in accordance with ISO 76.The static load rating is that load at which the Hertzian stress between the rolling elements and raceways reaches the following value at the most highly loaded point:

|

| 4200 MPa Ball bearing(except self-aligning ball bearings) |

| 4000 MPa Roller bearing |

|

The stress causes a permanent deformation at the contact point of 0.0001 of the rolling element diameter under normal contact condition.

|

Static safety factor Static safety factor |

|

The basic load rating Cor is used to select bearing size in case where the bearings are rotating at very slow speeds (n<10 r/min), subjected to very slow oscillation movements, or stationary under load during certain periods. It is also of the most importance to check the safety factors of short duration load such as shock or heavy peek load that acts on a rotary bearing or the bearing at rest.

|

| |

|

|

| where |

: static safety factor (see table of) : static safety factor (see table of) |

: static load rating (KN) : static load rating (KN) |

: equivalent static load (KN) : equivalent static load (KN) |

.jpg) Equivalent static load Equivalent static load |

|

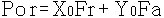

For application that existing both actual axial and radial load, they must be converted into an equivalent static load Por, which can be obtained from the equation.

|

|

| where |

| Fr :actual radial load (KN) |

| Fa :actual axial load (KN) |

| X0 :radial static load factor |

|

(see table of X0,Y0 ) |

| Y0 :axial static load factor |

| |

.jpg) |

| |

| |

|

|