|

.jpg) Bearing materials Bearing materials

|

|

The performance and operating reliability of bearing have been influenced significantly by material of which bearing components are made. For rolling bearings, which accommodate repeatedly high contact stress at the area between rings and rolling elements, must keep high precision operation. Therefore, material of bearings must have the properties of high hardness for high load carrying capacity and fatigue resistance, low friction & wear, and excellent dimensional stability. The properties of cage material are required to be able to overcome oscillation and shock stress during the revolution ,at the mean time, reduce friction between rolling elements and rings while having properties of light weight and suitability for operating temperature environment. Seal material must have traits of excellent anti-oxidation, heatproof, and anti-corrosion.

|

|

TCB is able to provide our customers with optimized products through designing & manufacturing various bearing rings, rolling elements, cages, seals by utilizing all different materials and implementing special manufacturing & coating processes.

|

.jpg) Materials of rings and rolling elements |

|

High carbon chromium steel GCr15

|

|

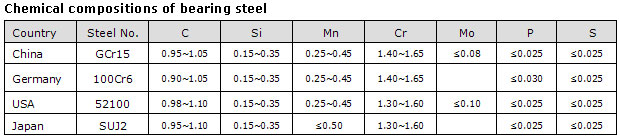

High carbon chromium steel is the most appropriate material of which rolling bearings are made. Its chemical compositions are as follows:

|

|

|

In order to ensure the stability and reliability of rolling bearings, TCB persists to use high purity bearing steel which has infinitesimal oxygen and other detrimental non-metallic substances.

|

| Stainless steel and coating |

|

Stainless steel bearings or bearings with special coating shall be recommended for the stringent corrosion resistant applications. For additional information about alternative coating, please consult TCB’ s application engineers.

|

|

.jpg) Materials of cages Materials of cages

|

| Pressed steel cages |

|

Pressed steel cages are used in most of TCB rolling bearings. The majority of them are made of cold or hot rolled low carbon sheet steel, some of them also are of stainless steel sheet. Those light weight cages have high strength and can be variously surface-treated to reduce friction and wear.

|

Polymer material cages

Polyamide 6,6 |

|

Polyamide 6,6 is the most common material for injecting moulded cage. Polyamide 6,6 with glass fibre reinforcement or without it has favorable properties of strength, elasticity and anti-corrosion. The recommended operating temperature ranges from -20¡æ¡« +80¡æ since it is inclined to be aged under the higher temperature.

|

| Polyether-ether-ketone (PEEK) |

|

Glass fibre reinforced poly-ether-ketone has been becoming popular to be regarded as the material for cages in recent years. Its combined merits like superior strength, flexibility, wide operating temperature range, anti-chemical corrosion & wear resistance, as well as good processability make it become the most suitable choice for applications in conditions regarding high speed, high temperature and chemical attack. Although it can be operated at temperature up to +200¡æ,the maximum temperature of application for high speed is limited to +150¡æ.

|

| Phenolic resin |

|

Fabric reinforced phenolic resin is the normal cage material for high precision angular contact ball bearings. The properties of light weight, anti-corrosion, shock-resistance, lubricating ability can withstand extreme high centrifugal force & acceleration force. Its recommended operation temperature only ranges from - 40¡æ ¡« +120¡æ since this material intends to fail at higher temperature.

|

.jpg) Materials of seals Materials of seals |

|

Synthetic rubber is the normal application for TCB bearing seals. There are several synthetic rubber materials available depending on different bearing series, dimensions, and applications.

|

| Nitrile-butadiene rubber (NBR) |

|

As a universal material for seals with the advantages of oil-resistance and waterproof, NBR can operate normally under operating temperature between - 40¡æ ¡« +100¡æ.Its instant extreme temperature reaches up to +120¡æ.The lips of seal made of this material can adapt to oil-free condition for a short duration.

|

| Hydrogenated nitrile-butadiene rubber (HNBR) |

|

Compared with NBR,HNBR has more intensive abilities in anti-friction,heatproof, anti-age and stiffness-resistance. Therefore, the seals made of it can find more extensive engineering applications with better life in the circumstance of heat-oil and ozone. The operation temperature reaches up to +150¡æ,much higher than NBR’s.

|

| Fluorous rubber (FPM) |

|

Beware of that FPM emits toxic gas when working at temperature beyond +300¡æ.

The most outstanding advantages of FPM are its abilities to endure high temperature and resist corrosion while keeping the distinctive properties of anti-oxidation & ozone, poor gas permeability and low friction. It also can operate when exposed to various oil, lubricant, inorganic acid, aliphatic hydrocarbon and dutrex. All these merits make it become the ideal sealing material that operating in extreme ambient circumstance, but the operation temperature shall not exceed +200¡æ

|